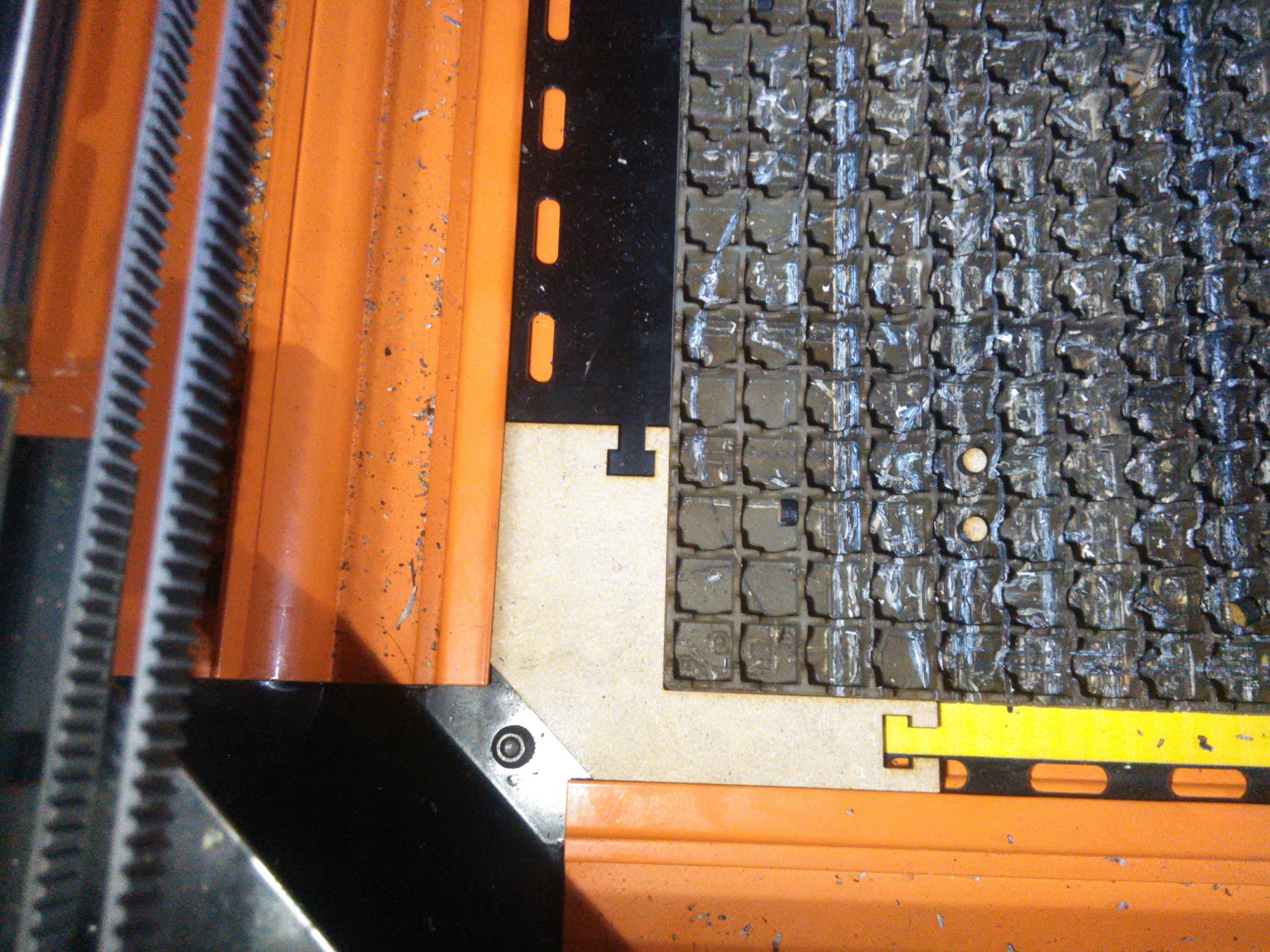

like my lasercutter, it does it's job and I've made all sorts of things with it.

But it's rubber mats tend to move a bit every time I place or take out an mdf plate.

That makes it a bit difficult to exactly align each new plate, so even if I cut out

several of the same designs, I have to perform an outline check and make small

adjustments to the positioning in the software.

It's mostly my clumsiness that makes the rubber mats move around.

But it can still be annoying and time consuming to be fiddling with the positioning

every time. To solve this, I've designed a corner piece that fits in the lasercutter

and holds the bottom two mats in place.

It's same piece, cut out twice and flipped over to make the opposite corner.

They do their job well and hold the two bottom mats firmly in place.

I've already included connector holes in the design, so that if I want to I can

put in more support pieces and perhaps also lock the top two mats down.